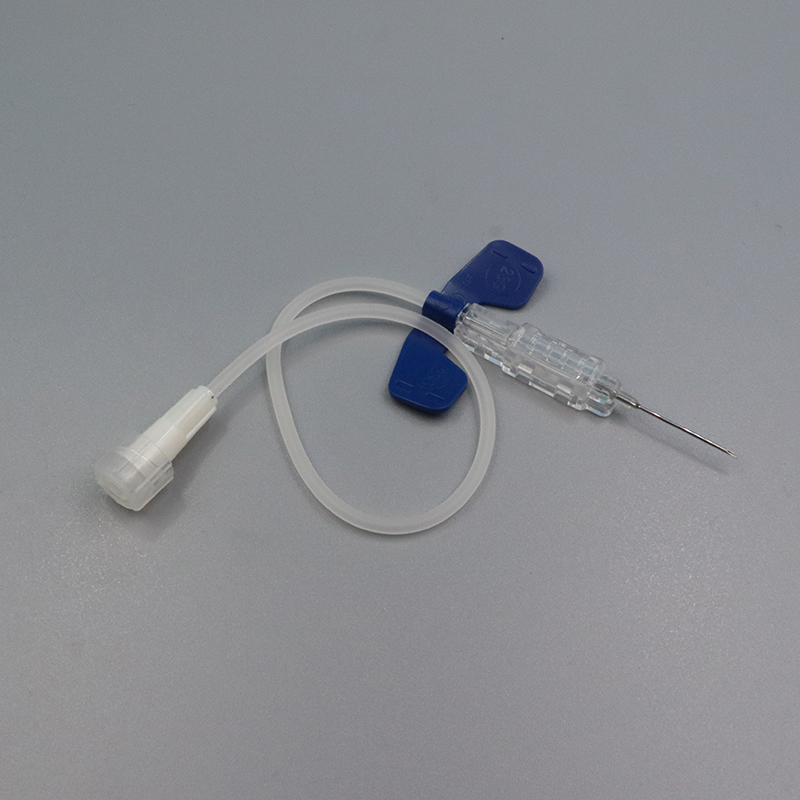

Syringes Needle Manufacturers in China: Quality and Affordability

When I think about sourcing quality syringes and needles, I always turn to reliable manufacturers in China. These syringes are essential for medical facilities and clinics, and I know that partnering with a trusted supplier can make all the difference. The precision and reliability of these products are what I value most, as every detail matters in a medical environment. What I appreciate are the various types of syringes and needles available. From disposable options to specialized designs, they meet diverse needs. Plus, manufacturers in China often offer competitive pricing without compromising on quality, making it easier for me to manage budgets without sacrificing patient care. I have found that working with these suppliers leads to efficient delivery and support, which is crucial for maintaining a steady supply. If you are a B2B purchaser looking for high-quality syringes and needles, China’s manufacturers are definitely worth considering.

Syringes Needle in 2025 Pioneers in the Field

The global landscape for medical supplies is evolving rapidly, and by 2025, the syringe and needle market is set to witness transformational changes. With advancements in technology and heightened demand for safe, efficient, and eco-friendly medical devices, the industry is gearing up for innovative solutions that cater to both healthcare providers and patients globally. As we move towards a more interconnected world, the emphasis on quality and reliability of syringes and needles will be paramount. Suppliers will increasingly focus on offering products that not only meet stringent regulatory standards but also enhance user experience. The integration of smart technologies, such as electronic monitoring of dosage and usage, is just one example of how the industry is adapting to new healthcare needs. Sustainability will also become a focal point in the manufacturing of medical supplies. With climate change concerns at the forefront, there will be a shift towards biodegradable materials and recycling programs that minimize waste. This approach not only aligns with global sustainability goals but also appeals to conscious consumers and procurement teams alike. As we approach 2025, staying ahead of these trends will be crucial for suppliers looking to thrive in the ever-competitive market.

Syringes Needle in 2025 Pioneers in the Field

| Category | Material | Needle Gauge | Usage | Innovation Features |

|---|---|---|---|---|

| Standard Syringes | Polypropylene | 23G | General Injection | Ergonomic design for better grip |

| Safety Syringes | Polycarbonate | 21G | Vaccination | Automatic needle retraction |

| Insulin Syringes | Glass | 30G | Diabetes Management | Fine calibration for accurate dosing |

| Pre-Filled Syringes | Plastic | 25G | Monoclonal Antibodies | Ready-to-use with dose accuracy |

| Specialty Syringes | Silicone Coated | 18G | Cell Therapy | Smooth flow and reduced tissue damage |

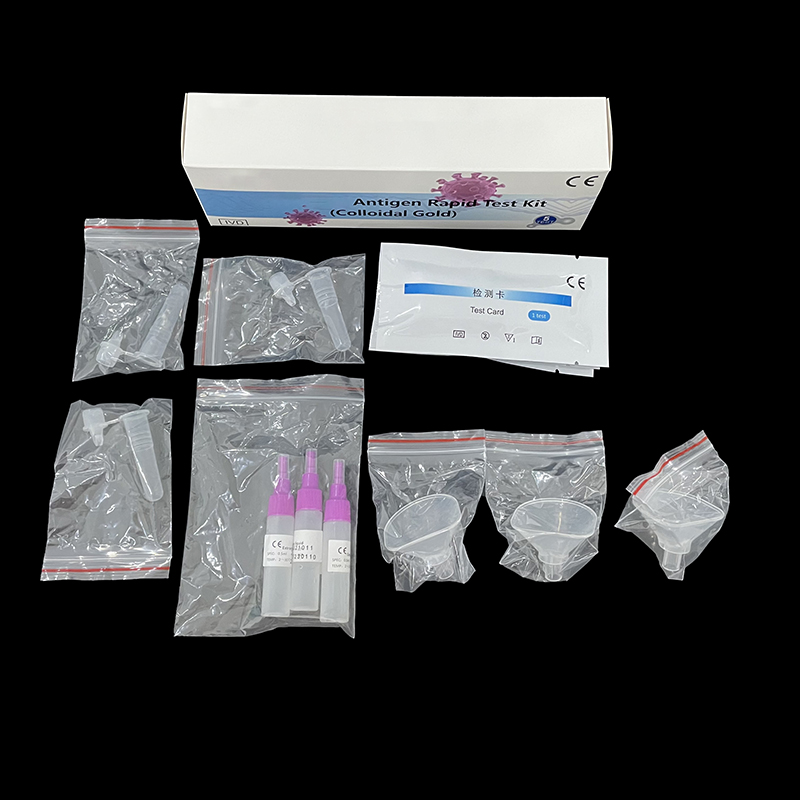

Related Products