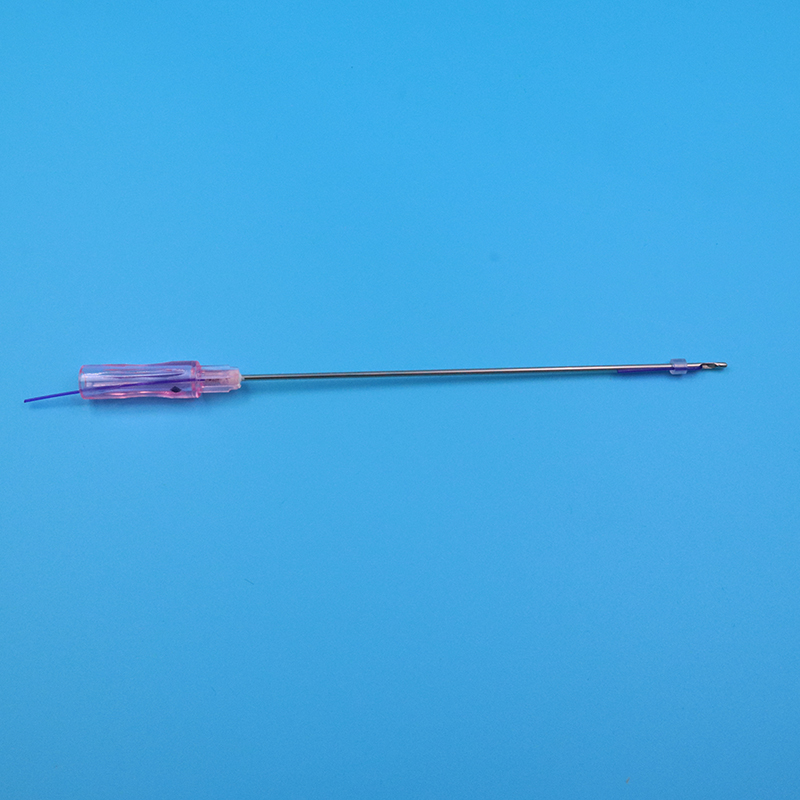

Nylon Suture Manufacturers in China: Quality Solutions for Your Needs

As a leading manufacturer of nylon sutures in China, I know the importance of quality and reliability in surgical materials. Our nylon sutures are crafted with precision to ensure optimal tensile strength and minimal tissue reaction, making them ideal for a variety of surgical procedures. We source the best raw materials and implement stringent quality control measures, so you can trust that our products meet international standards. I understand the critical role these sutures play in your practice and aim to provide consistent performance and excellent value for your investment. Whether you’re in a busy hospital or a smaller clinic, our nylon sutures are designed to meet the diverse needs of healthcare professionals. Partner with us today and experience the difference in quality that our China-based manufacturing can offer. Your patients deserve the best, and that starts with the right tools for the job.

Nylon Suture Now Trending Your Trusted OEM Partner

In the rapidly evolving landscape of medical supplies, nylon sutures have emerged as a popular choice among healthcare professionals worldwide. Known for their excellent tensile strength and minimal tissue reaction, these sutures are ideal for a variety of surgical applications. As more healthcare providers seek reliable products that ensure patient safety and quick recovery times, nylon sutures are gaining traction and becoming a staple in operating rooms globally. Partnering with an experienced OEM provider can streamline your supply chain and offer access to high-quality nylon sutures tailored to your specific needs. By leveraging advanced manufacturing techniques and adhering to international quality standards, an OEM partner can help you navigate the complexities of global procurement while maintaining competitive pricing. With their expertise, you can focus on delivering exceptional care while ensuring that your supply of medical devices remains uninterrupted and dependable. As the demand for nylon sutures continues to rise, collaborating with a trusted OEM partner can set your business apart in the competitive medical supply market. By investing in quality products and utilizing the right manufacturing support, you can enhance your reputation and strengthen your position as a preferred supplier in the healthcare sector. Embrace this trend and watch your business flourish as you meet the needs of healthcare professionals around the globe.

Nylon Suture Now Trending Your Trusted OEM Partner

| Suture Type | Diameter (mm) | Length (cm) | Needle Type | Color | Material |

|---|---|---|---|---|---|

| Nylon Monofilament | 0.5 | 45 | 3/8 Circle | Black | Nylon |

| Nylon Braided | 0.7 | 60 | 1/2 Circle | Blue | Nylon |

| Nylon 3-0 | 0.3 | 75 | Reverse Cutting | Green | Nylon |

| Nylon 4-0 | 0.2 | 50 | Taper Point | Transparent | Nylon |

Related Products