As the global incidence of chronic kidney disease continues to rise, demand for high-quality hemodialysis catheters is increasing rapidly. Hospitals, dialysis centers, and international distributors are now paying more attention to sourcing safe, advanced, and durable long term hemodialysis catheters from trustworthy suppliers. Choosing the right hemodialysis catheters manufacturer not only affects patient safety but also impacts clinical performance and long-term business success.

This article explains what dialysis catheters are, the common types of dialysis catheter, the features of long-term catheters, and how to properly evaluate a manufacturer—especially for buyers seeking reliable production partners in China.

What Are Hemodialysis Catheters?

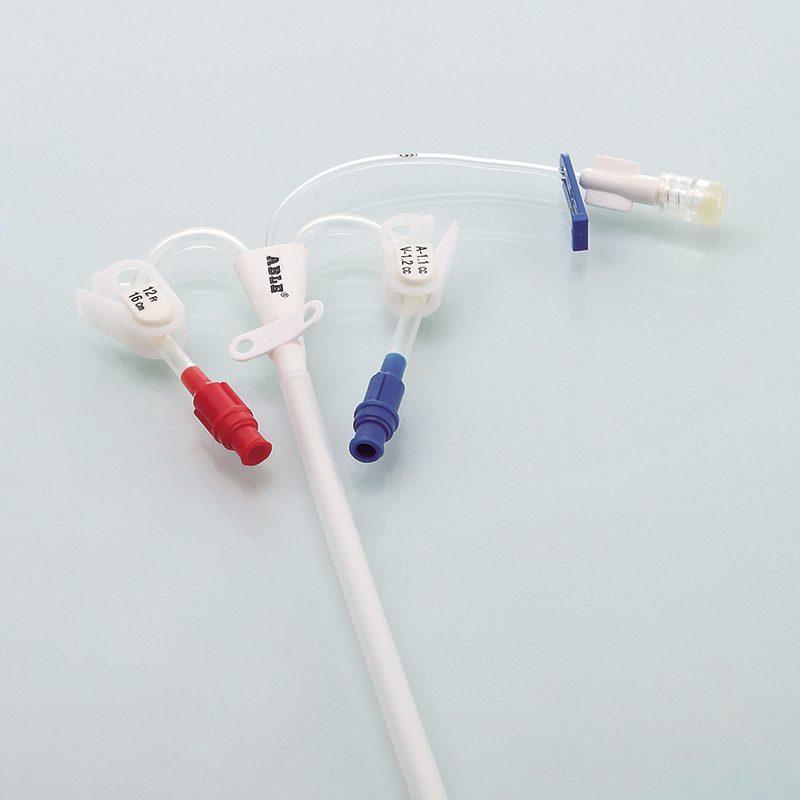

A hemodialysis catheter is a sterile, flexible medical device inserted into a large central vein to provide immediate vascular access for dialysis treatment. It allows blood to flow from the patient’s body to the dialysis machine, where toxins and excess fluid are removed before the blood returns to the patient.

Hemodialysis catheters are widely used when AV fistulas or grafts are not feasible, or when rapid access is needed. For long-term dialysis patients, catheter durability and infection resistance are crucial.

Types of Dialysis Catheter

Understanding the main types of dialysis catheter helps healthcare providers and distributors select the most suitable products.

1. Temporary Hemodialysis Catheters

For acute or emergency dialysis

Inserted percutaneously

Suitable for short-term use (hours to weeks)

2. Long Term Hemodialysis Catheters (Tunneled Catheters)

Used for months or years

Surgically tunneled to reduce infection

Equipped with cuffs for secure placement

3. Dual-lumen and Triple-lumen Catheters

Dual-lumen for standard dialysis

Triple-lumen for simultaneous infusion or medication administration

4. Special Tip Designs (Split-tip, Step-tip)

Improve flow performance

Reduce recirculation and clot formation

Dialysis Catheter Types Comparison Table (table 1)

| Type of Dialysis Catheter | Intended Use | Duration of Use | Key Features | Advantages | Common Materials |

| Temporary Hemodialysis Catheter | Acute kidney failure, emergency dialysis | Hours to weeks | Non-tunneled, bedside insertion | Fast insertion, immediate access | Polyurethane |

| Long Term Hemodialysis Catheter (Tunneled) |

Chronic dialysis | Months to years | Tunneled, cuffed, antimicrobial options | Lower infection risk, stable flow | Polyurethane, silicone |

| Dual-Lumen Catheter | Standard hemodialysis | Short- or long-term | Two lumens for arterial/venous flow | Efficient dialysis, widely used | Polyurethane |

| Triple-Lumen Catheter | Dialysis + infusion therapy | Short- or long-term | Three lumens | Multi-purpose treatment | Polyurethane |

| Split-tip / Step-tip Catheters | High-efficiency dialysis | Long-term | Special tip geometry | Reduced recirculation | Polyurethane or silicone |

What Makes Long Term Hemodialysis Catheters Different?

Unlike temporary catheters, long term hemodialysis catheters are engineered for durability, stability, and safety over months or years of continuous use.

Key characteristics include:

Biocompatible Materials

Soft polyurethane or silicone ensures patient comfort and reliable blood flow.

Tunneled Design

Reduces bacterial migration and keeps the catheter securely positioned.

Antimicrobial & Antithrombogenic Coatings

Prevent bacterial buildup and clot formation, extending catheter lifespan.

Cuffed Structure

The Dacron cuff promotes tissue ingrowth, stabilizing the catheter.

High Flow Performance

Special lumen and tip designs improve dialysis efficiency and reduce treatment time.

Key Benefits of High-Quality Long Term Catheters (table 2)

| Feature | Clinical Benefits | Importance for Long-Term Dialysis |

| Biocompatible materials | Less irritation, improved comfort | Reduces complications over long durations |

| Tunneled design | Lower infection risk | Essential for chronic therapy |

| Antimicrobial coating | Prevents clotting & bacterial growth | Extends catheter life |

| High flow performance | Faster, more efficient dialysis | Shorter treatment time |

| Cuffed placement | Prevents dislodgement | Ensures long-term stability |

Why Choosing the Right Hemodialysis Catheters Manufacturer Matters

The quality of a dialysis catheter heavily depends on the manufacturer’s technical strength and production standards. Partnering with the right supplier leads to:

1. Higher Patient Safety

Certified manufacturers follow strict quality systems such as ISO 13485, CE, and FDA requirements.

2. Better Performance and Durability

High-level engineering ensures consistent blood flow without kinking, collapsing, or clotting.

3. Reduced Infection Rates

Advanced surface treatments and secure cuffed designs significantly reduce catheter-related infections.

4. Stable Supply Chain

Hospitals and distributors require uninterrupted access to essential medical devices.

How to Choose a Reliable Long Term Hemodialysis Catheters Manufacturer

Below is a practical checklist for evaluating a supplier—especially if you are sourcing from Asia or looking for a trustworthy hemodialysis catheters manufacturer in China.

1. Check Certifications and Regulations

Look for manufacturers with:

ISO 13485

CE Marking

FDA 510(k) or registration

2. Evaluate Manufacturing Capabilities

A professional catheter factory should have advanced extrusion equipment, precise molding machines, and automated assembly lines.

3. Review Product Range

The supplier should offer:

Temporary and long term hemodialysis catheters

Multiple sizes and lumen options

Custom tip designs

4. Assess Sterilization Quality

Reliable EO sterilization or gamma irradiation ensures safe, sterile products.

5. Compare Pricing and OEM/ODM Support

Manufacturers in China often provide competitive pricing, private-label customization, and high production efficiency—ideal for global distributors.

Manufacturer Evaluation Checklist Table (table 3)

| Evaluation Criteria | What to Look For | Why It Matters |

| Certifications | ISO 13485, CE, FDA | Ensures product safety & compliance |

| Production capability | Dedicated catheter production lines | Consistent performance & quality |

| R&D strength | Custom designs, improved coatings | Helps your product stand out |

| Product range | Multiple types of dialysis catheter | Covers all clinical needs |

| Sterilization method | EO or gamma | Guarantees reliable sterility |

| OEM/ODM services | Custom packaging, branding | Supports distributors and exporters |

| Pricing | Factory-direct, competitive rates | Improves profit margins |

| After-sales support | Technical documents, training | Reduces customer risk |

Conclusion

Selecting the right long term hemodialysis catheters manufacturer is essential for ensuring safe, reliable, and effective dialysis treatment. By understanding the different types of dialysis catheter, key performance features, and critical evaluation criteria, you can build long-term partnerships with manufacturers that deliver consistent quality—especially those in China with strong production capabilities.

A dependable supplier not only improves clinical outcomes but also helps distributors expand globally with confidence.

Post time: Nov-24-2025