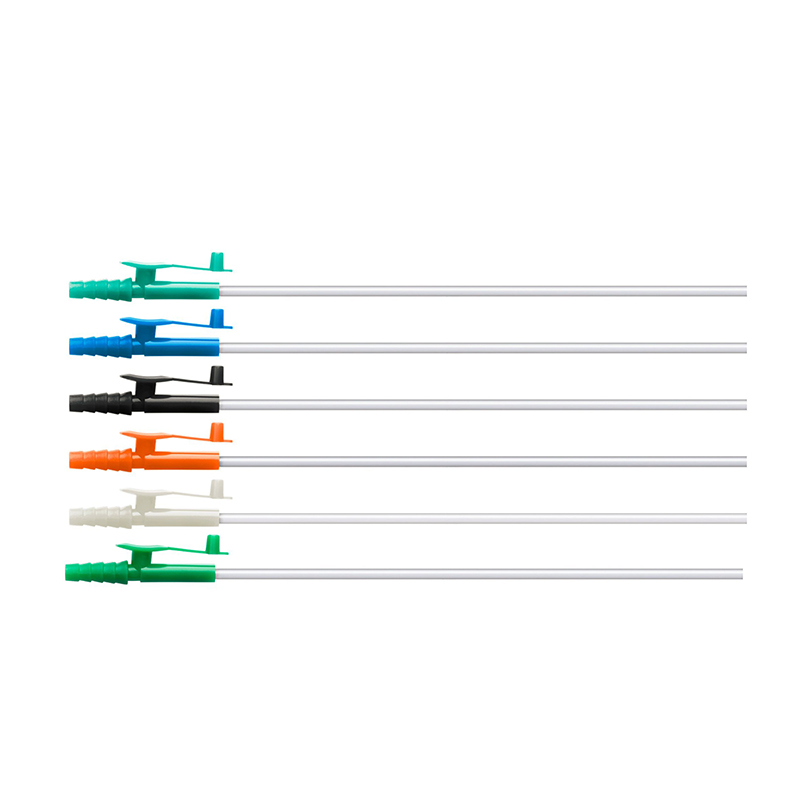

Medical Closed Suction Catheter: Leading OEM Supplier Options Available

When it comes to providing optimal respiratory care, I rely on our Medical Closed Suction Catheter. Designed for ease of use and maximum patient comfort, this catheter offers a reliable solution for suctioning in critical care settings. Working closely with trusted OEM suppliers, I ensure that our catheters meet the highest quality standards while remaining cost-effective for healthcare facilities. With an emphasis on durability and effectiveness, these catheters are engineered to reduce the risk of infection and improve patient outcomes. Whether you're a hospital procurement officer or a medical distributor, partnering with us means accessing top-tier products that align with your needs. I’m dedicated to providing you with the best options in the market, and our Medical Closed Suction Catheters are no exception. Reach out today to explore how we can support your supply chain requirements with exceptional products and service.

Medical Closed Suction Catheter in 2025 Where Service Meets Innovation

In the ever-evolving landscape of medical technology, the year 2025 marks a significant turning point for closed suction catheter systems. These devices, essential for efficient airway management, are experiencing a wave of innovation that not only enhances functionality but also prioritizes patient safety and user comfort. As global procurement professionals seek reliable and effective solutions, the latest advancements are set to redefine standards in clinical settings worldwide. The introduction of smart technologies in closed suction catheters is particularly noteworthy. These innovative devices integrate sensors that monitor suction levels and provide real-time feedback to healthcare providers, ensuring optimal performance during critical procedures. This seamless connection between technology and service streamlines workflows and minimizes the risk of complications, ultimately leading to improved patient outcomes. As the demand for advanced medical solutions grows, procurement teams must consider these cutting-edge products that promise to enhance efficiency and elevate care quality. Furthermore, sustainability in medical device manufacturing is becoming increasingly important. In 2025, leading manufacturers are focusing on eco-friendly materials and processes that reduce environmental impact without compromising product efficacy. This shift aligns with global health initiatives aimed at promoting sustainable practices in healthcare, appealing to procurement professionals looking to meet both operational and ethical standards. Embracing these innovations not only positions organizations at the forefront of medical advancements but also showcases a commitment to enhancing patient care and environmental responsibility.

Medical Closed Suction Catheter in 2025 Where Service Meets Innovation

| Feature | Description | Benefits | Innovation Aspect |

|---|---|---|---|

| Anti-Backflow Valve | Prevents contamination during suction. | Increased safety for patients. | Utilizes advanced valve technology. |

| Flexible Design | Conforms to various anatomical structures. | Enhanced comfort during use. | Incorporates new materials for flexibility. |

| Integrated Monitoring | Real-time feedback on suction pressure. | Improved decision making for healthcare providers. | Incorporates smart sensor technology. |

| User-Friendly Interface | Easy to understand controls and indicators. | Reduced learning curve for new users. | Designed with user experience in mind. |

| Sustainable Materials | Manufactured using eco-friendly materials. | Minimizes environmental impact. | Aligns with global sustainability goals. |

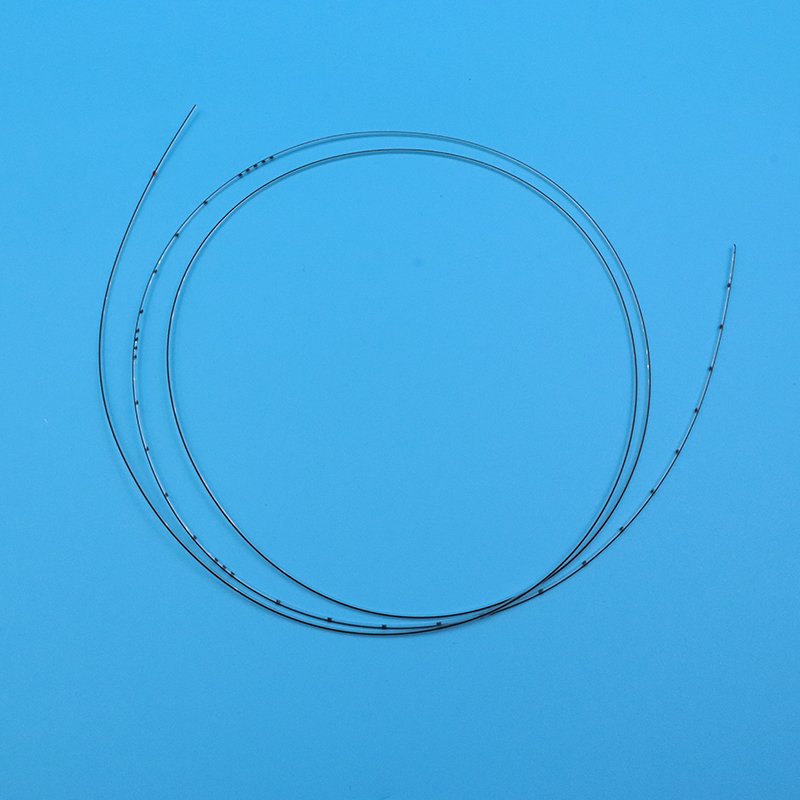

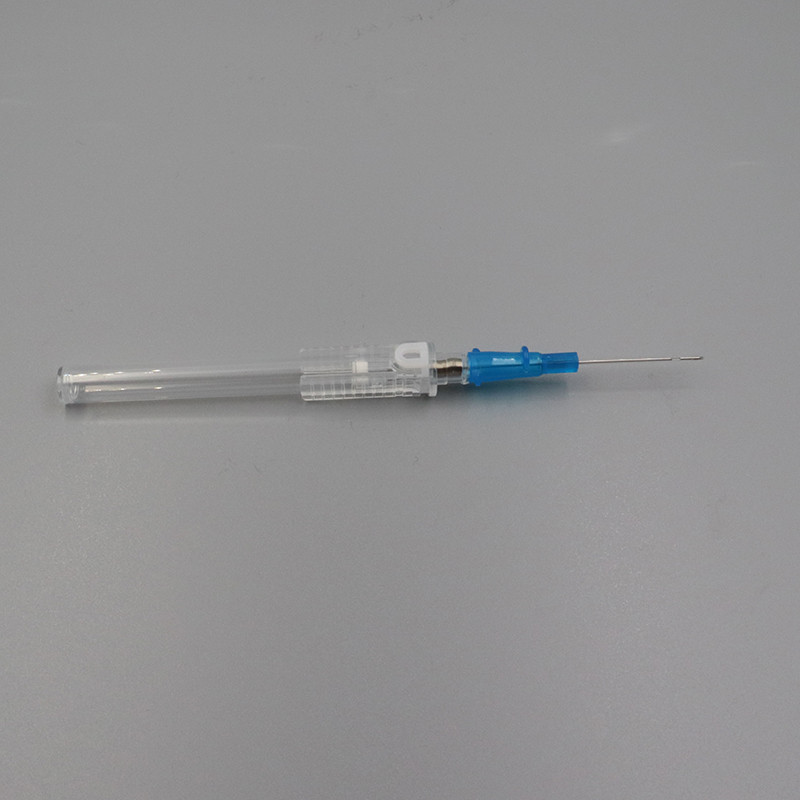

Related Products