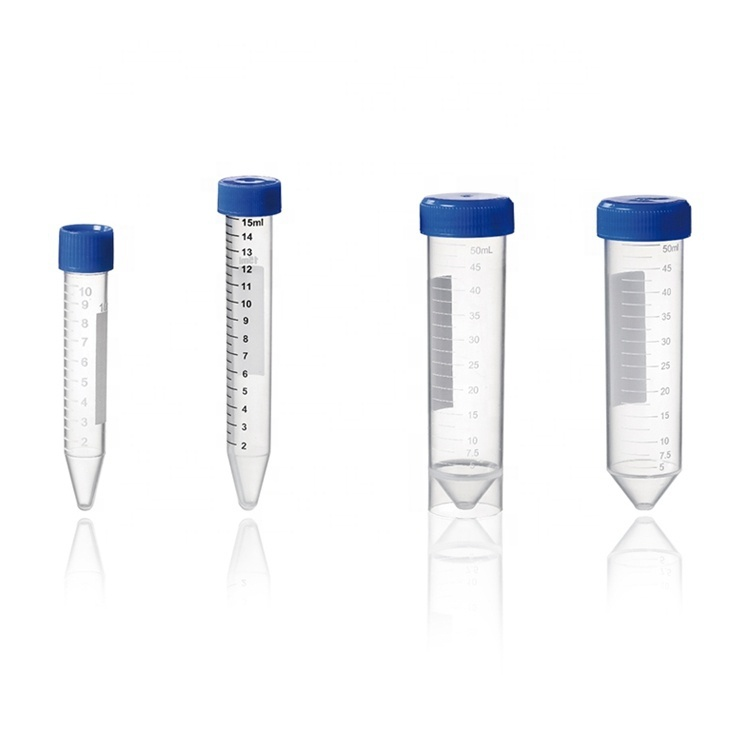

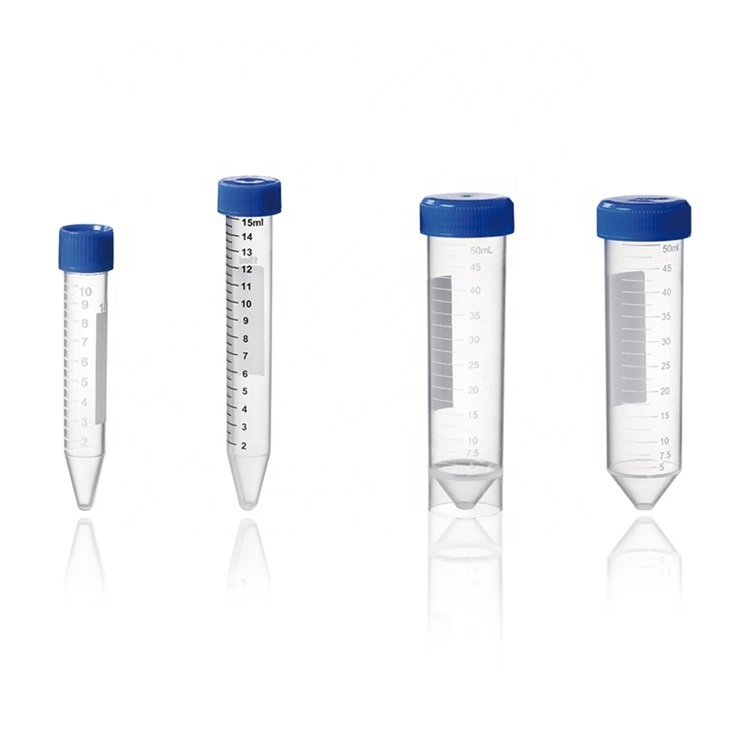

Cryo Tube ODM Suppliers: Quality Solutions for Your Cryogenic Needs

As a B2B purchaser, I always aim for quality and reliability, and that’s exactly what our Cryo Tube offers. These tubes are perfect for preserving biological samples at ultra-low temperatures. I trust their design, which ensures no leakage or contamination. With options for ODM services, I can get customized solutions that perfectly match my lab's needs. Suppliers like us prioritize durability and performance, so I know I'm investing in a product that delivers long-lasting results. Plus, the ease of use means my team can focus on what they do best—research and innovation. By choosing our Cryo Tube, I'm not just purchasing a product; I’m securing peace of mind and supporting the integrity of my projects. If you're also in search of reliable cryogenic solutions, let’s connect and see how we can work together to enhance your laboratory's capabilities.

Cryo Tube in 2025 From Concept to Delivery

In 2025, the landscape of cryogenic solutions is set to experience transformative advancements, and the concept of the Cryo Tube is at the forefront. As industries worldwide seek innovative technologies to enhance efficiency and sustainability, the Cryo Tube emerges as a vital component for various applications, from medical storage to industrial processes. Designed for optimal performance, this cutting-edge product promises to revolutionize how we handle and store temperature-sensitive materials, offering unmatched reliability and safety. The journey from concept to delivery involves meticulous research and development. As manufacturers strive to meet the diverse needs of global buyers, they engage in rigorous testing and validation to ensure that the Cryo Tube exceeds industry standards. This commitment to quality not only enhances the product's functionality but also instills confidence in partners and customers alike. In a world where precision is paramount, the transition from an innovative idea to a readily available solution involves collaboration across various sectors, paving the way for broader adoption and integration into existing workflows. Looking ahead, it is clear that the Cryo Tube will play a crucial role in advancing technology across multiple industries. Buyers can expect a product that not only addresses current challenges but also provides a sustainable path forward. As we approach 2025, the anticipation surrounding the launch of the Cryo Tube symbolizes a pivotal moment in the evolution of cryogenic solutions, poised to meet the demands of an increasingly dynamic global market.

Cryo Tube in 2025 From Concept to Delivery

| Phase | Description | Expected Completion Date | Key Stakeholders | Success Metrics |

|---|---|---|---|---|

| Concept Development | Initial design and specifications for the cryo tube. | 2023 Q4 | R&D Team, Medical Advisors | Feasibility Study, Initial Prototypes |

| Prototyping | Creating functional prototypes for testing and validation. | 2024 Q2 | Engineering Team, User Testing Group | Performance Testing, User Feedback |

| Regulatory Approval | Submitting documentation for approval from health authorities. | 2024 Q4 | Compliance Officers, Regulatory Bodies | Approval Status, Compliance Checks |

| Manufacturing | Setting up manufacturing processes for mass production. | 2025 Q1 | Production Managers, Supply Chain Team | Production Volume, Quality Control |

| Market Launch | Launching the product into the market with promotional activities. | 2025 Q2 | Marketing Team, Sales Team | Sales Targets, Market Penetration |

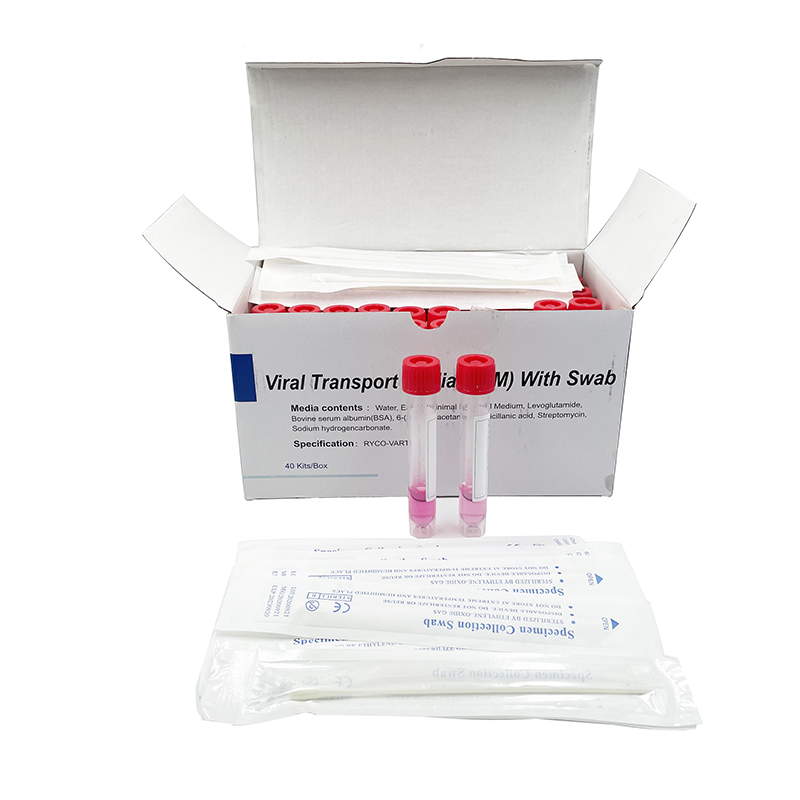

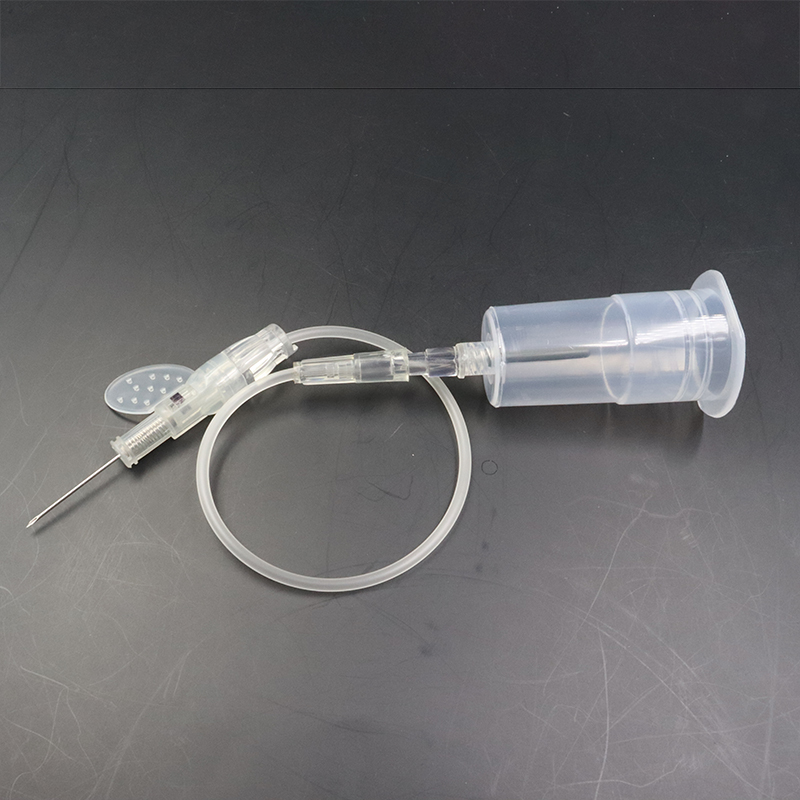

Related Products